China Wholesale High Speed Plastic Injection Molding Machine

Quality comes first; service is foremost; business is cooperation” is our business philosophy which is constantly observed and pursued by our company for China Wholesale High Speed Plastic Injection Molding Machine, We just not only offer the good quality to our clients, but more even important is our greatest support along with the competitive cost.

Quality comes first; service is foremost; business is cooperation” is our business philosophy which is constantly observed and pursued by our company for China Thin Wall Plastic Making Machine and Plastic Millk Tea Cup Making Machine, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer’s wider and higher requirement in recent years. We’ve been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Basic Info:

M8 Series: 88 Ton Precise & Energy Saving Plastic Injection Molding Machine

Model: HMD88M8/M8-s

Machine Technical Date:

|

DESCRIPTION |

Unit |

HMD128 M8/M8-S |

||

|

International size rating |

416/128 |

|||

|

INJECTION UNIT |

A |

B |

C |

|

|

Shot volume |

cm3 |

129 |

163 |

201 |

|

Shot weight(PS) |

g |

117 |

148 |

183 |

|

oz |

4.1 |

5.2 |

6.5 |

|

|

Injection rate |

cm3/s |

67 |

85 |

105 |

|

Screw diameter |

mm |

32 |

36 |

40 |

|

Injection pressure |

MPa |

214 |

169 |

137 |

|

Screw L:D ratio |

L/D |

23:1 |

20:1 |

18:1 |

|

Screw stroke |

mm |

160 |

||

|

Screw speed (stepless) |

r/min |

0~215 |

||

| CLAMPING UNIT | ||||

|

Clamping force |

kN |

880 |

||

|

Opening stroke |

mm |

320 |

||

|

Platen size |

mm |

550 x 550 |

||

|

Space between tie-bars (HxV) |

mm |

360 x 360 |

||

|

Max. daylight |

mm |

680 |

||

|

Mold thickness (Min-Max) |

mm |

150~360 |

||

|

Ejector stroke |

mm |

100 |

||

|

Ejector force |

kN |

31 |

||

| POWER UNIT | ||||

|

Hydraulic system pressure |

MPa |

16 |

||

|

Pump motor power |

kW |

7.5/11.6 |

||

|

Heating capacity |

kW |

7 |

||

|

Number of temp control zones |

/ |

4 |

||

| GENERAL | ||||

|

Oil tank capacity |

L |

180 |

||

|

Machine dimensions (LxWxH) |

m |

4.4 x 1.04 x 1.83 |

||

|

Machine weight |

kg |

3500 |

||

Processing Equipment:

Certificate:

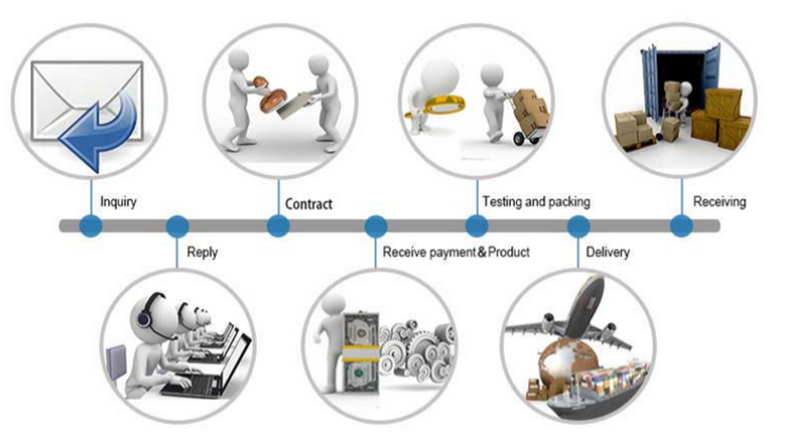

Our Service:

Quality comes first; service is foremost; business is cooperation” is our business philosophy which is constantly observed and pursued by our company for China Wholesale High Speed Plastic Injection Molding Machine, We just not only offer the good quality to our clients, but more even important is our greatest support along with the competitive cost.

China Wholesale China Thin Wall Plastic Making Machine and Plastic Millk Tea Cup Making Machine, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer’s wider and higher requirement in recent years. We’ve been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!